- Introduction

- Definition of Carbon Fiber

- The Importance of Density in Material Science

- Applications Where Density Plays a Critical Role

- The Chemical Structure of Carbon Fiber

- The Role of Carbon Atoms in Carbon Fiber

- How the Atomic Structure Affects Density

- The Relationship Between Atomic Arrangement and Material Weight

- The Molecular Bonding and Density of Carbon Fiber

- Covalent Bonds in Carbon Atoms

- Influence of Bonding on the Material’s Density

- The Significance of Molecular Alignment and Crystallinity

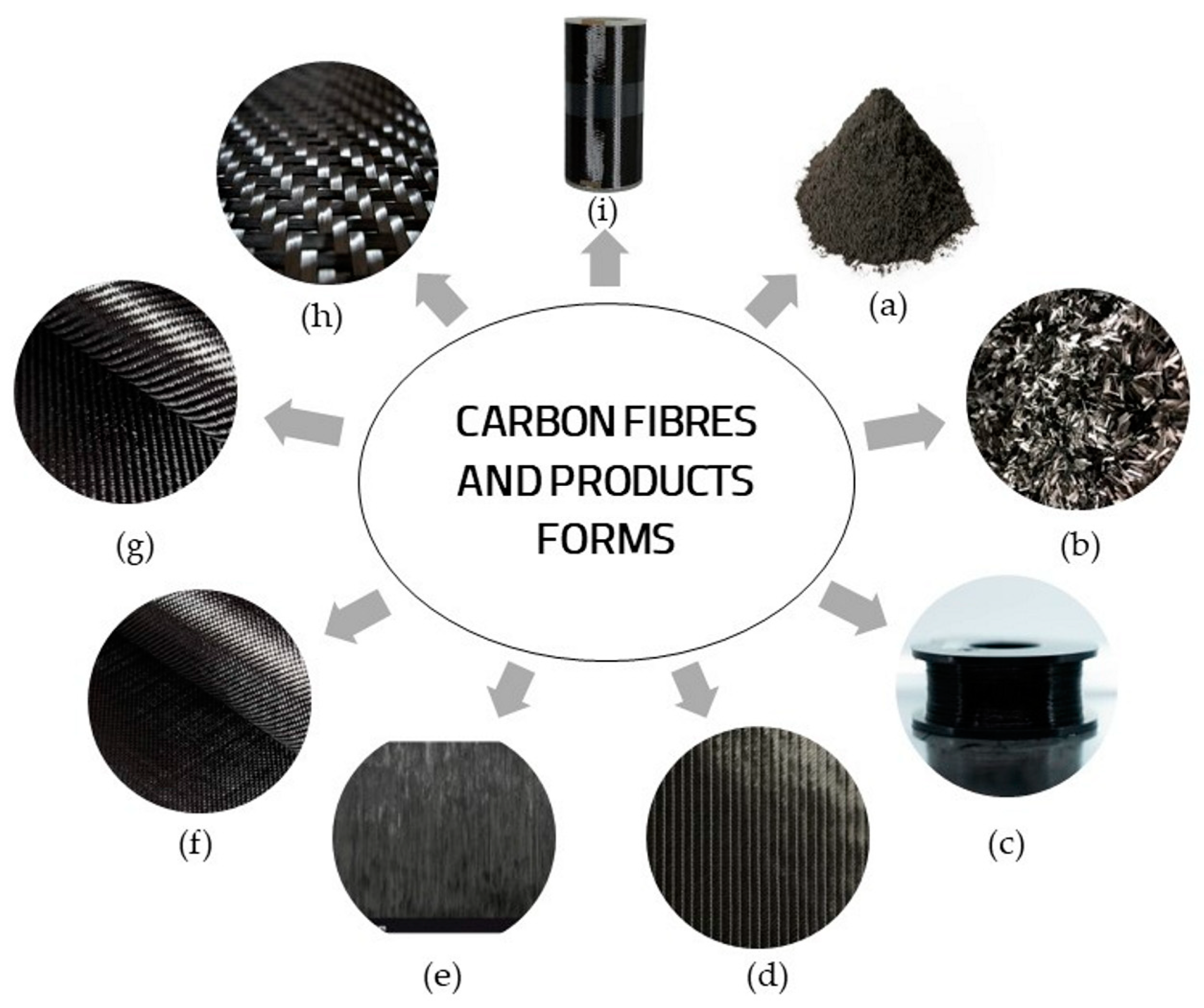

- The Manufacturing Process of Carbon Fiber

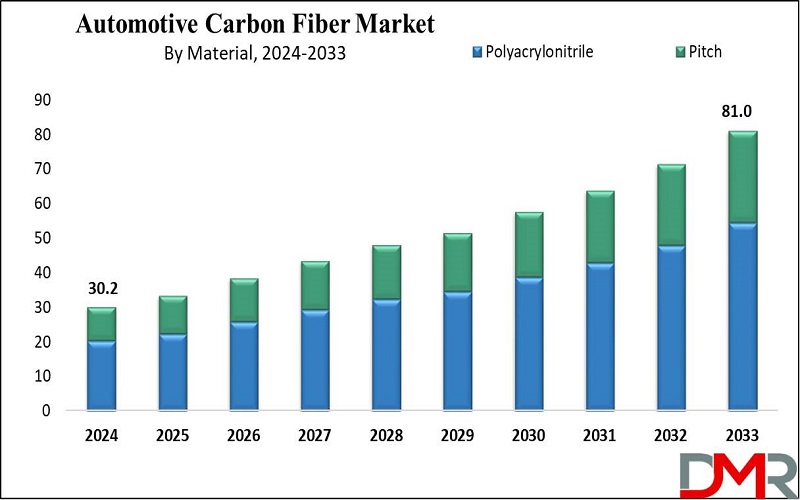

- Precursor Materials: PAN and Pitch

- Stabilization and Carbonization

- Fiber Formation and Its on Density

- The Role of Heat and Pressure in Material Density

- Carbon Fiber’s Low Density Compared to Other Materials

- Carbon Fiber vs. Steel: Density Differences and Performance

- Carbon Fiber vs. Aluminum: Weight and Strength Considerations

- Carbon Fiber vs. Other Composite Materials

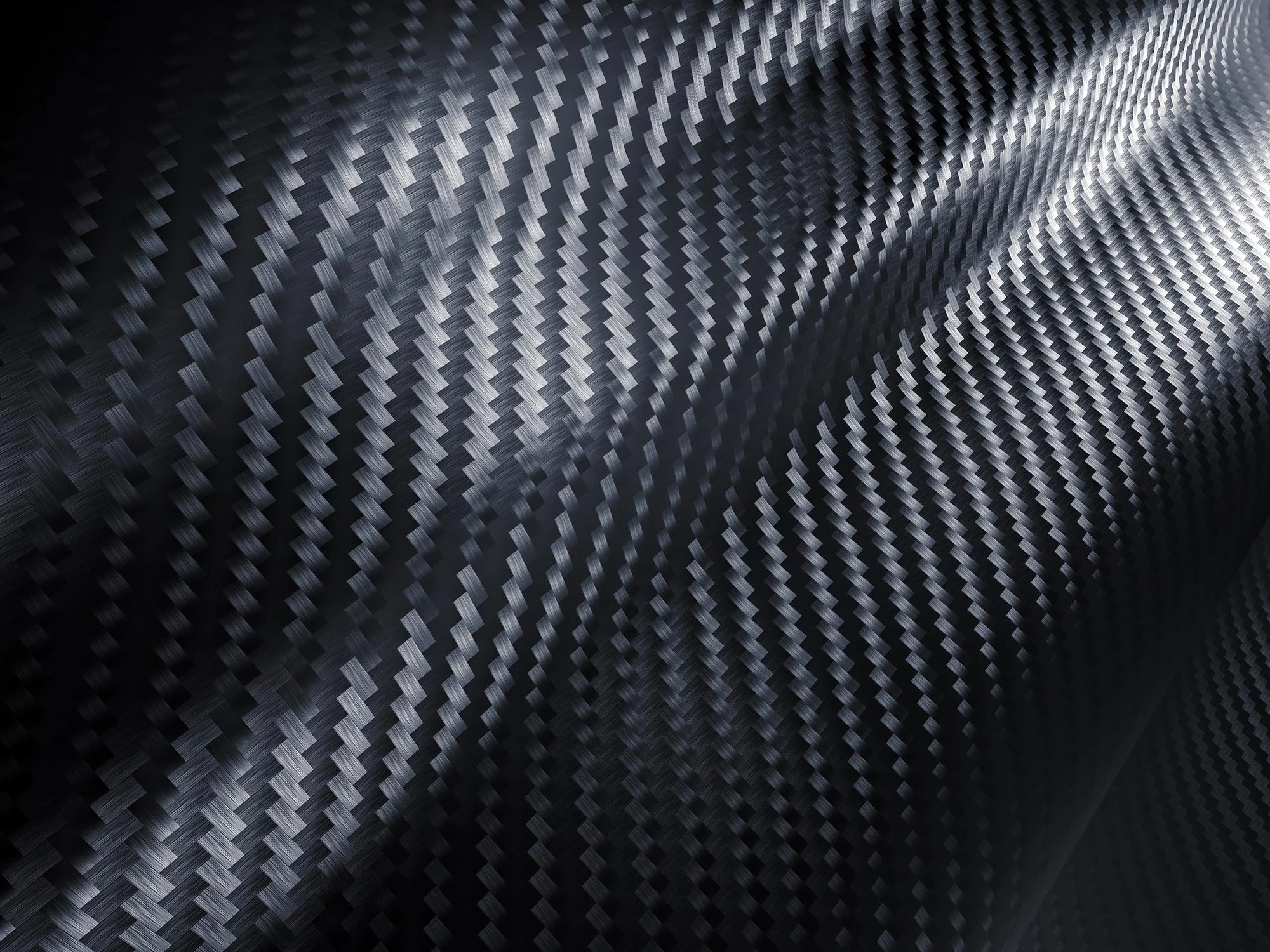

- Influence of Fiber Orientation on Density

- Unidirectional Carbon Fiber vs. Multidirectional Fiber

- How Fiber Alignment Affects Density and Mechanical Properties

- The Importance of Fiber Arrangement in Composite Materials

- The Role of Resin and Matrix Materials in Carbon Fiber Composites

- Epoxy and Other Resin Materials

- The Interaction Between Fiber and Matrix in Determining Overall Density

- How Resin Content Affects the Final Density of the Composite

- Applications of Low-Density Carbon Fiber

- Aerospace Industry: Lightweighting Aircraft and Spacecraft

- Automotive Industry: Improving Fuel Efficiency and Performance

- Sports Equipment: Enhancing Performance with Low-Density Materials

- Advancements in Carbon Fiber Technology

- Innovations in Low-Density Carbon Fiber Production

- Future Trends in Material Science and Carbon Fiber’s Role

- Sustainability and the Environmental of Low-Density Materials

- Conclusion

- Summary of the Factors Contributing to Low Density

- Future Developments in Carbon Fiber Technology

- The Importance of Density in Determining Carbon Fiber’s Versatility

1. Introduction

Definition of Carbon Fiber

Carbon fiber is a synthetic material made from carbon atoms arranged in long, thin fibers. These fibers are incredibly strong and lightweight, which makes them highly desirable in industries where strength and low weight are essential. Carbon fiber is primarily used in composite materials—a combination of carbon fiber and a resin matrix to enhance mechanical properties such as strength, stiffness, and durability.

The Importance of Density in Material Science

Density is a crucial property in material science because it defines how much mass a material has per unit volume. In simpler terms, density refers to the compactness of a material’s atoms and molecules. For many applications, especially in aerospace, automotive, and sports industries, low-density materials are preferred to reduce weight without sacrificing strength. The lower the density, the lighter the material, which translates to better performance and energy efficiency.

Applications Where Density Plays a Critical Role

Low-density materials like carbon fiber are extensively used in fields where weight reduction is critical. These include the aerospace industry, where weight reduction directly fuel efficiency and performance; the automotive industry, where lighter vehicles lead to better fuel economy and handling; and the sports equipment industry, where strength-to-weight ratio plays a key role in product performance.

2. The Chemical Structure of Carbon Fiber

The Role of Carbon Atoms in Carbon Fiber

At its core, carbon fiber consists of carbon atoms that are bonded together in a linear or crystalline structure. Carbon, a non-metal element, has unique properties that make it ideal for the creation of fibers with a low density. When carbon atoms bond, they form strong covalent bonds, which result in a rigid and stable structure. The simplicity of the atomic structure of carbon allows for the formation of light but strong bonds, contributing to the material’s low density.

How the Atomic Structure Affects Density

The atomic arrangement in carbon fiber is one of the key reasons for its low density. Carbon atoms are arranged in either amorphous or crystalline forms. The crystalline arrangement of the carbon atoms in carbon fiber is highly efficient, meaning that the atoms are packed tightly together without excess voids. However, carbon fibers are still lighter than many metals and alloys due to the simplicity of the atomic structure and the relatively low atomic mass of carbon itself.

The Relationship Between Atomic Arrangement and Material Weight

In carbon fiber, the alignment of carbon atoms in a parallel fashion creates long chains, which are then packed into bundles to form fibers. These fibers are incredibly strong because of the tightly bonded carbon atoms, but the overall weight is low because the material itself has a relatively small atomic mass. The high degree of order in the crystalline structure of the carbon atoms is what allows the material to be so light yet strong.

3. The Molecular Bonding and Density of Carbon Fiber

Covalent Bonds in Carbon Atoms

The strength and low density of carbon fiber are fundamentally due to the covalent bonds between the carbon atoms in the fibers. Covalent bonds involve the sharing of electrons between atoms, creating a stable and efficient molecular structure. In carbon fiber, these bonds are highly stable and strong, but the overall size and mass of the carbon atoms are relatively small, which keeps the fiber lightweight.

Influence of Bonding on the Material’s Density

The covalent bonds in carbon fiber provide strength without adding excessive weight. Since carbon atoms are among the lightest elements in the periodic table, their covalent bonding does not require heavy atoms, which is one reason why the density of carbon fiber is so low.

The Significance of Molecular Alignment and Crystallinity

The alignment of the carbon fibers plays a critical role in its mechanical properties and density. Crystallinity refers to the degree to which the atoms are arranged in an orderly, repeating pattern. Higher crystallinity leads to increased strength, but the highly ordered atomic arrangement can also contribute to a lightweight structure, as the carbon atoms are efficiently packed without wasteful spaces.

4. The Manufacturing Process of Carbon Fiber

Precursor Materials: PAN and Pitch

The production of carbon fiber begins with the selection of precursor materials. The most common precursor is polyacrylonitrile (PAN), which is polymerized to form long chains that are then processed into fibers. Another precursor material is pitch, which is derived from petroleum. These precursors are carefully chosen for their ability to be processed into fibers that retain the desired low density.

Stabilization and Carbonization

Once the precursor materials are chosen, the fibers undergo a two-step process called stabilization and carbonization. During stabilization, the fibers are heated to a moderate temperature in air to make them thermally stable. In the subsequent carbonization step, they are heated to extremely high temperatures (above 1000°C) in an inert atmosphere, which transforms the material into carbon fiber. This process increases the crystallinity of the carbon atoms, thereby enhancing the strength and keeping the material’s density low.

Fiber Formation and Its on Density

The process of fiber formation also plays a role in determining the density of carbon fiber. The fibers are extruded from the precursor material, and their thickness and length are adjusted to meet specific requirements. The smaller and more uniform the fibers are, the more efficiently they can be packed together, and the lower the density of the final product.

The Role of Heat and Pressure in Material Density

Throughout the manufacturing process, heat and pressure are applied to help align the carbon fibers in a specific direction. The more uniform the fiber alignment, the stronger and lighter the resulting material becomes. The careful control of temperature and pressure during the carbonization process ensures that the material remains low-density while maximizing strength.

5. Carbon Fiber’s Low Density Compared to Other Materials

Carbon Fiber vs. Steel: Density Differences and Performance

Carbon fiber is much lighter than steel. Steel has a density of around 7.85 g/cm³, while carbon fiber has a density of about 1.6 to 2.0 g/cm³. This makes carbon fiber approximately four to five times lighter than steel, yet it can achieve similar or superior strength, making it an ideal material for lightweight, high-strength applications.

Carbon Fiber vs. Aluminum: Weight and Strength Considerations

Compared to aluminum, which has a density of around 2.7 g/cm³, carbon fiber is still lighter. This lightweight nature of carbon fiber leads to reduced fuel consumption and increased performance in applications like aerospace and automotive industries, where weight reduction is crucial for efficiency and speed.

Carbon Fiber vs. Other Composite Materials

When compared to other composite materials, carbon fiber stands out as the material of choice for applications requiring high strength-to-weight ratios. Other composites, such as glass fiber or Kevlar, may have similar strength but are typically heavier and less efficient in terms

of density.

6. Influence of Fiber Orientation on Density

Unidirectional Carbon Fiber vs. Multidirectional Fiber

The orientation of the fibers in carbon fiber also affects its density. Unidirectional carbon fiber, where all fibers are aligned in one direction, tends to be lighter and stronger in that direction. In contrast, multidirectional carbon fiber (woven fibers) may have a slightly higher density due to the additional matrix material required for bonding the fibers.

How Fiber Alignment Affects Density and Mechanical Properties

The arrangement of the fibers within the carbon composite influences both the density and the mechanical properties of the material. Fibers that are aligned in a unidirectional fashion will create a more lightweight structure, whereas multidirectional fibers might require more bonding agents, thereby increasing the material’s density slightly.

The Importance of Fiber Arrangement in Composite Materials

Proper fiber arrangement is essential in balancing density and strength in composite materials. Advanced manufacturing techniques allow for precise control over fiber placement, which contributes to the efficiency of the final composite and its overall low density.

7. The Role of Resin and Matrix Materials in Carbon Fiber Composites

Epoxy and Other Resin Materials

Carbon fiber is often combined with resin materials such as epoxy, polyester, or vinyl ester to form a composite. The choice of resin affects the final density of the material, as resin is denser than carbon fiber. The resin content is controlled to minimize the additional weight while still ensuring the strength and durability of the final product.

The Interaction Between Fiber and Matrix in Determining Overall Density

The density of carbon fiber composites depends not only on the fibers themselves but also on how well the fiber and matrix materials interact. The fiber-matrix interface plays a significant role in the composite’s mechanical properties and overall density.

How Resin Content Affects the Final Density of the Composite

The resin content is a balancing act; too much resin increases the weight of the composite, while too little can compromise the structural integrity of the material. Manufacturers carefully optimize the ratio of fiber to resin to achieve the best possible strength-to-weight ratio.

8. Applications of Low-Density Carbon Fiber

Aerospace Industry: Lightweighting Aircraft and Spacecraft

Carbon fiber’s low density makes it ideal for the aerospace industry, where reducing weight can lead to significant improvements in fuel efficiency, performance, and safety.

Automotive Industry: Improving Fuel Efficiency and Performance

In the automotive industry, the use of carbon fiber composites enables manufacturers to create lighter, stronger vehicles that improve fuel efficiency without sacrificing safety or performance.

Sports Equipment: Enhancing Performance with Low-Density Materials

In sports equipment, carbon fiber’s low density allows athletes to achieve higher performance through lighter gear that maintains durability and strength.

9. Advancements in Carbon Fiber Technology

Innovations in Low-Density Carbon Fiber Production

Recent innovations in carbon fiber production, such as the development of new precursor materials and more efficient manufacturing processes, have enabled the creation of carbon fibers with even lower densities.

Future Trends in Material Science and Carbon Fiber’s Role

As material science progresses, the demand for lighter, stronger materials will continue to grow, and carbon fiber will likely play an even more significant role in various industries, including automotive, aerospace, and energy storage.

Sustainability and the Environmental of Low-Density Materials

Sustainability is an increasingly important consideration in the production of carbon fiber. Efforts are being made to reduce the environmental of carbon fiber production, including developing recyclable carbon fibers and more energy-efficient manufacturing techniques.

10. Conclusion

In conclusion, carbon fiber’s small density is the result of its atomic structure, crystalline arrangement, and manufacturing process. This unique combination of factors allows carbon fiber to achieve a low density while maintaining impressive strength and durability. As technology continues to advance, carbon fiber’s role in industries that require low-density materials will only increase, making it a critical material for the future.